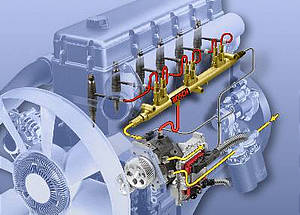

COMMONRAIL in D-4D Engine

All internal combustion engines need two key ingredients to operate: air and fuel. The precise delivery of these ingredients is what makes clean and powerful combustion possible. If you can get a large amount of air pumped in you increase the power of the engine and if you get large amount of fuel pumped in as well the power is enhanced even further. Turbochargers accomplish the first goal by helping deliver copious amounts of air to help diesels operate cleanly, efficiently and powerfully, commonrail accomplishes the second. High fuel pressure produces a fine mist of fuel that burns better and cleaner in the combustion chamber. Not only that, but for each combustion cycle, the common rail allows up to five injections per cycle. The driver benefits as lower fuel consumption (improved mileage), better engine performance and less noise compared with older diesels.

All internal combustion engines need two key ingredients to operate: air and fuel. The precise delivery of these ingredients is what makes clean and powerful combustion possible. If you can get a large amount of air pumped in you increase the power of the engine and if you get large amount of fuel pumped in as well the power is enhanced even further. Turbochargers accomplish the first goal by helping deliver copious amounts of air to help diesels operate cleanly, efficiently and powerfully, commonrail accomplishes the second. High fuel pressure produces a fine mist of fuel that burns better and cleaner in the combustion chamber. Not only that, but for each combustion cycle, the common rail allows up to five injections per cycle. The driver benefits as lower fuel consumption (improved mileage), better engine performance and less noise compared with older diesels.

Toyota D-4D diesel Engine is an efficient turbo intercooler engine in both 1-KD and 2-KD forms.

The way in which fuel is injected into the cylinders of diesel vehicles determines their torque, fuel consumption, emissions and noise level. Two factors are key: the fuel pressure as it enters the cylinder, and the shape and number of the injections.

A common rail injection system separates these two functions (generating pressure and injecting) by first storing fuel under high pressure in a central accumulator rail and then delivering it to the individual electronically-controlled injection valves (injectors). This ensures that incredibly high injection pressures (in some cases over 25,000 pounds per square inch) are available at all times.

The electronic injection system has multi-pilot injection control to determine the volume, timing and count interval between pilot injections and main injection. Click here to learn about other new diesel technologies.